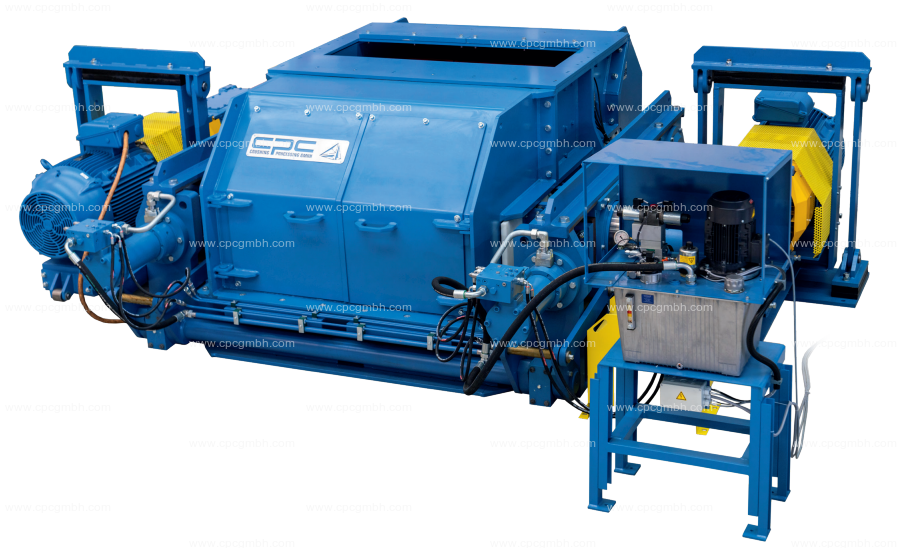

DOUBLE ROLL CRUSHER

DR13

Features

- Solution for medium-hard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc.)

- Weld-on hard-faced crushing teeth with various configurations for most difficult applications

- Integrated flywheel equalizing torque peaks, thus reducing required motor power

- Permanent parallel position of crushing rolls due to hydraulic “Cross Junction”, even in case of partial overload

- Efficient crushing of materials with less content of fines and low dust emissions

- Monitoring by local operator panel

Advantages

- Highest lifetime of crushing segments

- Fully automatic operation

- Generation of various degrees of product fineness

- High experience in custom-tailored product particle size distribution

- Fast and efficient maintenance of crushing segments

- Fully sensor-controlled to avoid downtimes

Application

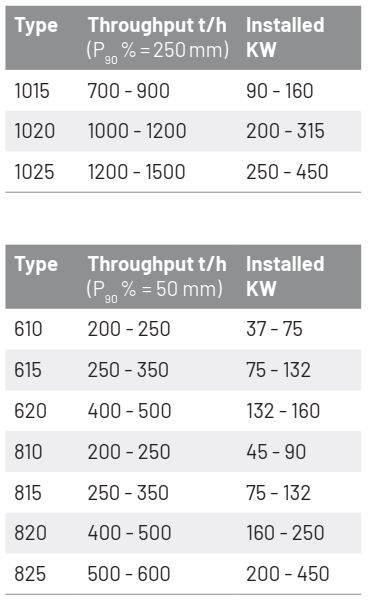

- Coarse size reduction of hard and medium-hard material (lime stone, magnesia, salt, fertilizer, coal etc.)

- Throughput up to 2.500 mt/hr, depending on material characteristic and particle size

- Feed material size up to 1.200 mm, product particle size from 10mm to 300mm possible, according customers demand

- Design of crushing teeth according to the material requirements (number, size, position, form, hardness)

- Integration in semi-mobile plants possible

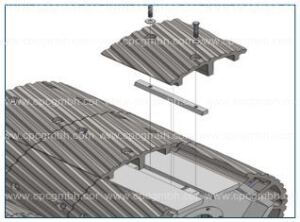

Mode of operation

- Crushing of the feed material by teeth as well by pressure, hydraulically induced. Successive comminution of larger lumps

- Product particle size regulated by precise setting of the roll gap

- Opening the gap between the crushing rolls in case of overload (e.g. caused by an unbreakable foreign object) within milliseconds to let that piece pass thus avoiding a shut-down

- No clogging of the rolls by sticky material due to specifically designed scrapers

- Final product with small portion of fines due to limited speed of the rolls

SOLUTION PROVIDER

Sustainable value enhancement of existing equipment with regards to

- Satisfying continuous operation

- Whole lifecycle