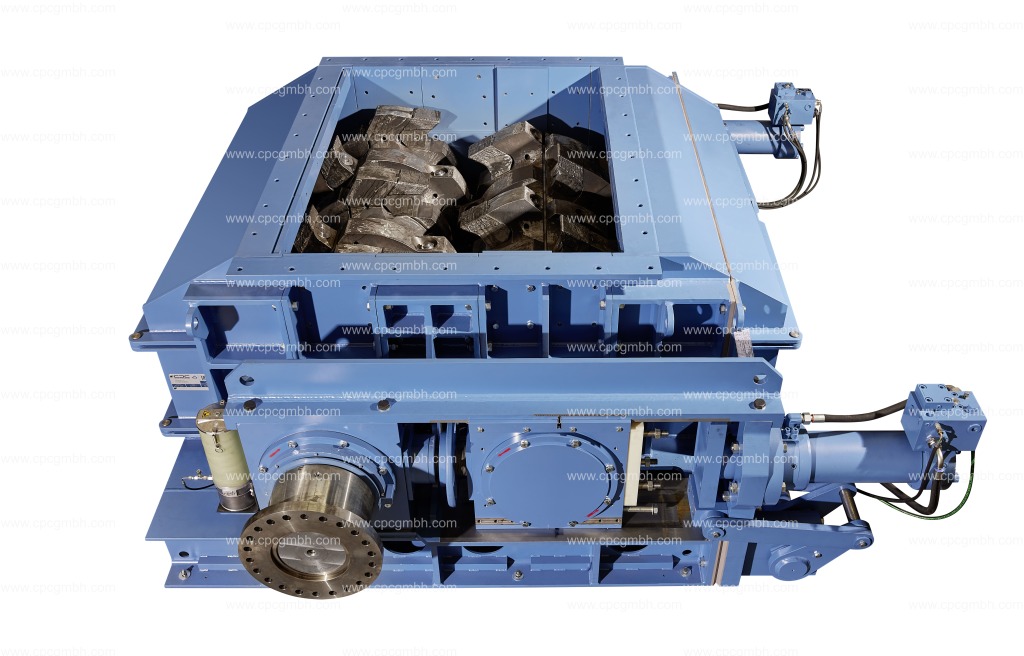

HYBRID CRUSHER

HC 15

Features

- Solution for hard, medium-hard, and soft materials (ores,

limestone, salt, coal, clay, oil shale etc.) - Weld-on hard-faced crushing teeth with various configurations

for most difficult applications - Integrated flywheel equalizing torque peeks, thus reducing

required motor power - Permanent parallel position of crushing rolls due to hydraulic

“Cross Junction” even in case of partial overload - Efficient crushing of material with less content of fines and low

dust emissions - Monitoring by local operator panel

PRIMARY STAGE

Crushing segments quick-change

SECONDARY STAGE

Crushing segments

Advantages

- Highest lifetime of crushing segments

- Fully automatic operation

- Generation of various degrees of product fineness

- High experience in custom-tailored product particle size distribution

- Fast and efficient maintenance of crushing segments

- Fully sensor-controlled to avoid downtimes

Application

- Coarse size reduction of hard, medium-hard and soft material (lime stone, dolomite, magnesia, salt, coal, clay, oil shale etc.)

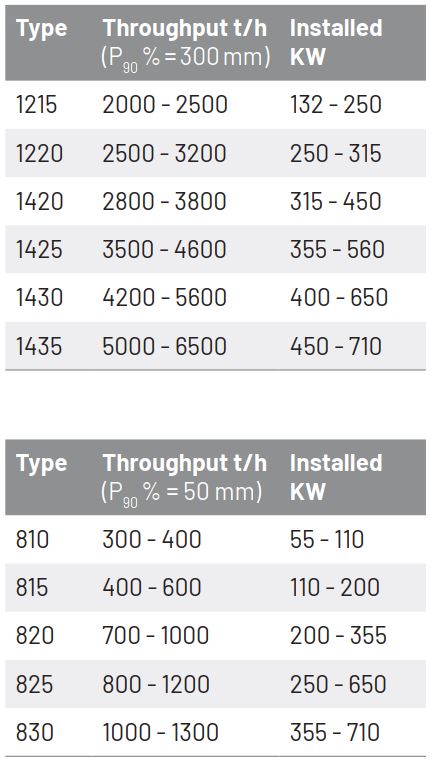

- Throughput up to5.500 mt/hr, depending on material characteristic and particle size

- Feed material size up to 1,500mm, product particle size down to 300mm possible, 50mm for secondary crushing stage

- Design of crushing teeth according to the material requirements (number, size, position, form, hardness)

Mode of operation

- Combination of the characteristic of the Double Roll Crusher with the performance of the Sizer

- Crushing of feed material by teeth of the two counter-rotating rolls. Successive comminution of larger lumps

- Product particle size regulated by precise setting of the roll gap

- Opening of the gap between the crushing rolls in case of overload (e.g. caused by an unbreakable foreign object) within milliseconds to let that piece pass thus avoiding a shut-down

- Crushing teeth in a spiral on the shaft equalizing torque peeks

- No clogging of the rolls by sticky material due to specifically designed scrapers

- Final product with small portion of fines due to limited speed of the rolls

SOLUTION PROVIDER

Sustainable value enhancement of existing equipment with regards to

- Satisfying continuous operation

- Whole lifecycle