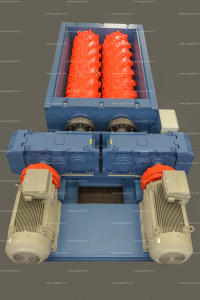

SIZER

SI 12

Features

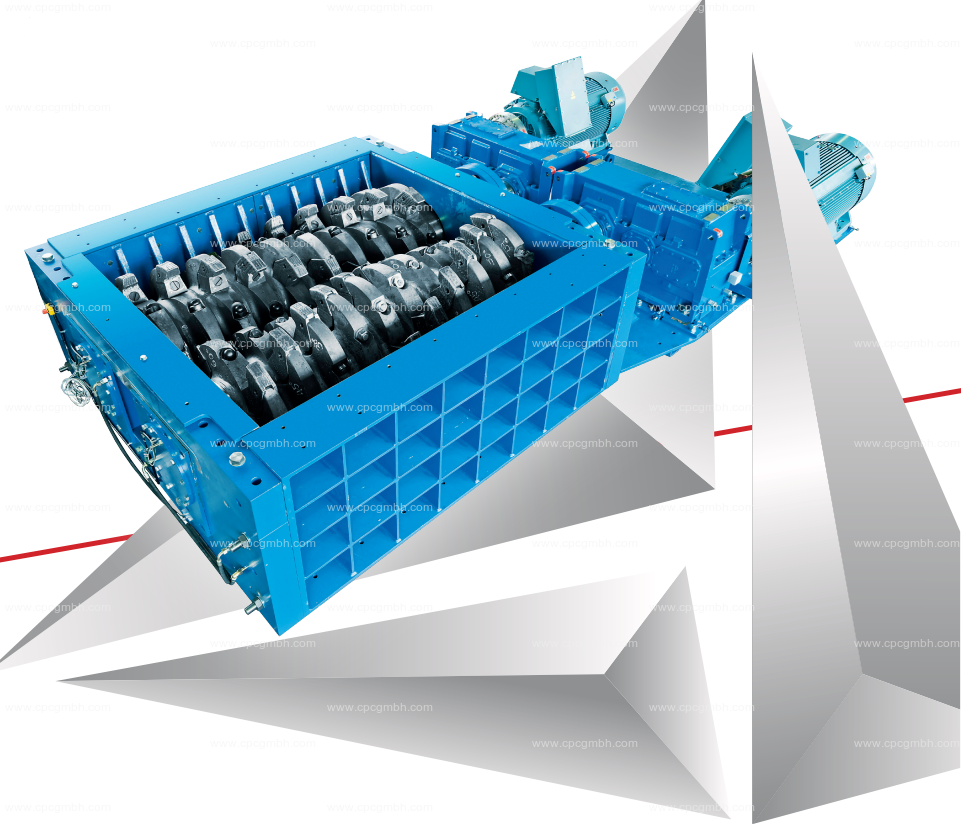

- Solution for medium-hard and soft materials (salt, coal,

phosphate, clay, etc.) - Heavy-duty, sturdy housing and wear liners for most difficult/

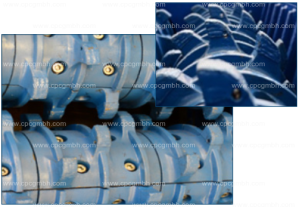

extreme applications - Weld-on hard-faced crushing teeth with various configurations

for most difficult applications - Crushing teeth arranged in a spiral on the shaft equalizing

torque peaks - Inclined side walls reduce the tendency to jam

- Final product with small portion of fines due to limited speed

of rolls - Monitoring by local operator panel

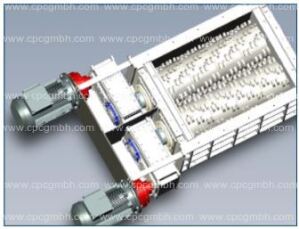

PRIMARY STAGE – CENTRE SIZER

Sizer teeth

SECONDARY STAGE – SIDE SIZER

Sizer with inward rorating rolls

Advantages

- Highest lifetime of crushing segments and teeth

- Fully automatic operation

- High experience in custom-tailored product particle size distribution

- Fast and efficient maintenance of crushing segments

- Discharge seal without the need of maintenance

- Fully sensor-controlled to avoid downtimes

Application

- Coarse size reduction of medium-hard and soft material (salt, coal, phosphate, clay etc.)

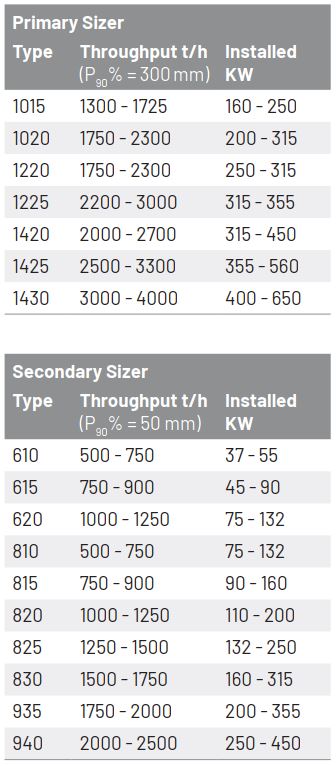

- Throughput up to 4.000 mt/hr, depending on material characteristic and particle size

- Feed material size up to 1.500mm, product particle size to 300 mm possible

- Design of crushing teeth according to the material requirements (number, size, position, form, hardness)

- Integration of Sizers in semi-mobile plants possible

Mode of operation

- Crushing of the feed material by the two counter-rotating rolls, either between inwards rotating rolls (Center Sizer) or between the outwards rotating rolls and the lined housing walls (Side Sizer). Successive comminution of larger lumps

- Fine feed material passes the rolls unhindered

- Typically the Center Sizers are employed for pre-crushing, Side Sizers for medium-crushing

- No clogging of the rolls by sticky material due to specifically designed scrapers

- Final product with small portion of fines due to limited speed of the rolls

SOLUTION PROVIDER

Sustainable value enhancement of existing equipment with regards to

- Satisfying continuous operation

- Whole lifecycle